INDUSTRIAL EQUIPMENT SOLUTIONS

Fields

Automobile

Cars and heavy load vehicles

Equipment and Public Works

Machinery constructions, infrastructure installations

Electrical and electronic equipments

Lighting, electricity, microelectronics

Water and Environment

Drinking water,

used water, process water

used water, process water

Transport

Aeronautics, Rail, Maritime, Heavy load vehicles

Heavy industry

Metallurgy

Research institutes

University laboratories, EPIC, EPCE

Energy and Chemistry

Energy production and distribution T&D, pharmaceutical industries

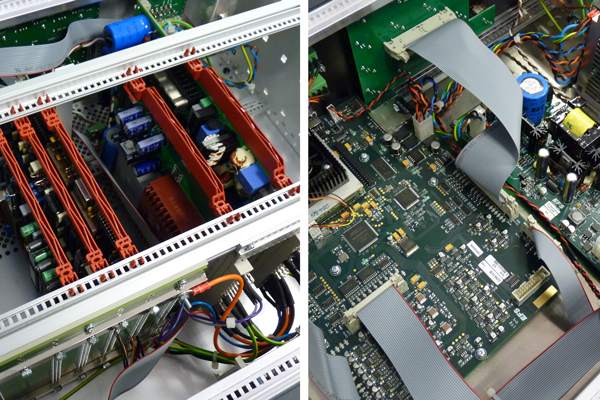

EFS EXPERTISES

Design of innovative products

Electronics – Mechanics – Software – Automation

Small and average series production

Components procurements Assembly and tests

Co-development project management

Idea – Solution – Industrialization – Production – After-sales service

EFS contribution is adapted for each situation

They trust us